Equipment Name: Batch-type Alkaline Polishing Equipment

Equipment Model: CC-PO-1000

Equipment Application: Used for polishing, etching and cleaning treatment of after diffusion wafers and also compatible for texturing and cleaning treatment of bifacial solar cells.

Process Flow:

Pre-cleaning→Polishing→Post-cleaning/O3 cleaning→Acid cleaning→Hot water drying→Drying (for reference only)

Features:

1. Throughput: 400pcs/batch,9600pcs/h(210 wafer),480pcs/batch,12000pcs/h(182 wafer).

2. Compatible with rear side etch polishing and rear side texturing process for mono-crystalline Si .

3. Suitable for various chemical additives.

4. Wafer thickness handling capability up to 120μm.

5. Designed with dry clean area and self-cleaning function.

6. Quick inline bath change.

7. Suitable with MES, RFID system, inline weight measuring option.

Suitable silicon wafer size: 18X/210/230mm;

Capacity: 15000pcs+/h (182*182mm, 120pcs/basket, total 6 baskets);

Mechanical handling arm: load>100kgf (designed with carbon fiber lightweight); Lateral movement speed @ 1500mm/s; Lifting speed @ 500mm/s;

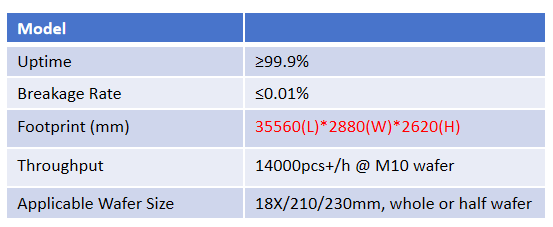

Equipment Uptime: ≥ 99.9%;

Wafer breakage rate: ≤ 0.01%;

Drying mode: slow lifting with cold water, fast drying at low temperature (400 seconds);

Automation: Suitable with MES, RFID, and optional online weighing functions; Support online liquid change and self-cleaning/drying function

电话:400-828-7520

电话:400-828-7520

传真:0086-510-86688139

传真:0086-510-86688139  邮箱:sales@cathcend.com

邮箱:sales@cathcend.com

地址:Building 3, No. 988 Gangcheng Avenue, Shengang Street, Jiangyin City, Wuxi City, Jiangsu Province

地址:Building 3, No. 988 Gangcheng Avenue, Shengang Street, Jiangyin City, Wuxi City, Jiangsu Province