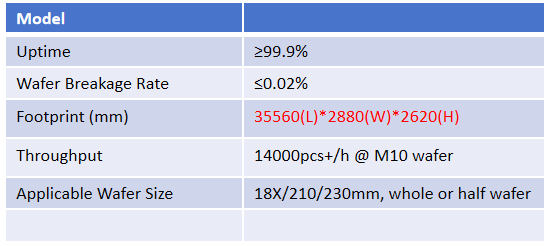

Equipment Name: Chain-type Acid Polishing Equipment

Equipment Model: CC-PO-1000

Equipment Application: This equipment is used for polishing, etching and cleaning treatment of diffused wafers and also compatible for texturing and cleaning treatment of bifacial solar cells.

Process Flow:

Load→Polishing→Rinse →Drying→ Unload

Features:

1. Throughput: 14000pcs/h(182 wafer).

2. Used for rear side etching and polishing process.

3. Suitable for various additives.

4. Wafer thickness handling capability up to 120μm.

5. With dry clean area and self-cleaning system.

6. Quick inline bath change.

7. Suitable with MES, RFID system, inline weight testing optional.

Belt traveling speed: 4.0+m/min, four sets of servo motors, with segmented increasing speed, can achieve low belt speed and high production capacity;

Fragmentation rate: ≤ 0.02%;

Water film: flow meter/manual diaphragm valve/pneumatic diaphragm valve control, with ± 3ml;

Drying: High cleanliness CPVC integrated molding air knife, fast drying;

Roller spacing: The distance between the process groove rollers is 45mm, with full bearing (widened) coverage.

电话:400-828-7520

电话:400-828-7520

传真:0086-510-86688139

传真:0086-510-86688139  邮箱:sales@cathcend.com

邮箱:sales@cathcend.com

地址:Building 3, No. 988 Gangcheng Avenue, Shengang Street, Jiangyin City, Wuxi City, Jiangsu Province

地址:Building 3, No. 988 Gangcheng Avenue, Shengang Street, Jiangyin City, Wuxi City, Jiangsu Province